15

2023-08

China Nerin Enabling Baiyin Group's Digital Transformation with Multiple Technologies

In recent years, Baiyin Nonferrous Group Co., Ltd. (also known as Baiyin Group) has embraced the digital development trend by formulating digital transformation plans to digitize the Group's entire industrial chain with the target to establish a high-end, intelligent, and environmentally friendly enterprise.

China Nerin, a long-standing partner of Baiyin Group, with extensive engineering experience and deep technical knowledge in the field of copper smelting, has introduced a range of automatic and intelligent digital solutions that have effectively supported the implementation of Baiyin Group's transformation. These solutions act as the “wings”, propelling the enterprise's digital transformation.

Evolving the automation system towards one-click intelligent control

The automation systems, commonly referred to as the "eyes" of a plant, play a critical role in ensuring production safety, cost-effectiveness, and efficiency. At Baiyin Group's flash furnace central control room, China Nerin has developed and implemented an online control system that collects real-time production data from various systems, including flash furnace blending, furnace vessel, waste heat boiler, and offgas handling. This system automatically executes production instructions in a sequential manner. The PLC (programmable controllers) of standalone equipment within the smelting plant, anode refining system, and sulfuric acid plant transmits data to the online control system through communication channels, which eliminates information silos, enables comprehensive production process control, and ensures seamless data connectivity throughout the smelter. The stable operation of this system is attributed to the dedication and expertise of China Nerin's technical team, who have committed themselves to the success of the project.

In May 2019, the project achieved a noteworthy milestone with the successful initial feed, marking a significant breakthrough in achieving a "one-time successful commissioning of the whole process." This accomplishment set a new industry record by attaining the designed throughput in the shortest possible time. Additionally, in December 2020, Baiyin Group's smelting plant and sulfuric acid plant were selected as the first batch of digital workshops in Gansu province.

Digital simulation system, the strongest “brain” in the plant

Copper smelting is an intricate production process that is influenced by numerous factors such as time, temperature, air, raw materials, and fuel. In the past, when manual operations were predominantly employed, it was exceedingly challenging to simultaneously consider the impacts of these various factors to ensure smooth production. However, through the utilization of big data analysis, coupled with advanced detection equipment and computer technology, China Nerin has independently developed a digital simulation system for flash smelting and converter blowing. This achievement holds substantial significance as it effectively facilitates the control of matte grade, matte temperature, and Fe-SiO2 ratio. Moreover, it enables the measurement of melt temperature in the converter, automatic determination of the endpoint in the converter, and enhancements in smelting recovery rate and furnace lifespan.

In the past, despite extensive experience, it was a challenging endeavor to accurately calculate the production process. Even the most seasoned workers, who had spent decades in the smelter, could not have anticipated that the introduction of a digital simulation system would provide a remarkable "brain" for production, allowing for effortless resolution of operational optimization issues such as material ratio in the feed, slag composition, and energy mediums. Today, with a simple click of a mouse, operators have real-time access to production data from each converter and can build models for analysis on their computers. This transformation has completely revolutionized the original production operation mode.

Intelligent consumption optimization platform, a "potent tool" for advancing low carbon emission reduction

The "Industrial Internet-based Intelligent Consumption Optimization Platform for Copper Smelting" developed by Baiyin Group was selected as one of the pilot demonstration projects for big data industry development by the Ministry of Industry and Information Technology in 2020. China Nerin mobilized a technical team to demonstrate the need for developing such a platform. They analyzed the relationship between energy consumption and outputs of intermediate or final products such as matte, blister, anode, and cathode, determined key areas of high energy consumption in the production process and equipment operation, identified weaknesses in energy management, and constructed the consumption optimization model. Their hard work eventually paid off as the platform went online at the end of 2021. This platform not only enables in-depth analysis and utilization of vast production data but also serves as the foundation for setting energy-saving targets for equipment and process transformations and optimization of management processes. A number of technical solutions and measures for energy saving, emission reduction, and improvement of quality and efficiency were implemented and have already yielded positive results. The proportion of low-grade feed to the flash furnace has increased from 15% to 25%, and the converter cycles per day have risen from 3.4 to 4 batches, leading to a 19% reduction in operating costs and a 10% decrease in unit product consumption.

Dynamic flue gas balance system maximizing synergy effect

Since Baiyin Group utilizes both its proprietary "Baiyin furnace" and the advanced "flash furnace", China Nerin has innovatively incorporated a dynamic flue gas balance system into the project. This system enables automatic interlock control for the sulfuric acid systems of both furnaces, as well as the associated gas exhaust fan and SO2 blower. It achieves dynamic balance of the flue gas, contributing to the continuous stable production of the metallurgical furnaces and a safe balance of the acid system. The Baiyin furnace and the flash furnace now complement each other in production, forming a system that exceeds the sum of its parts.

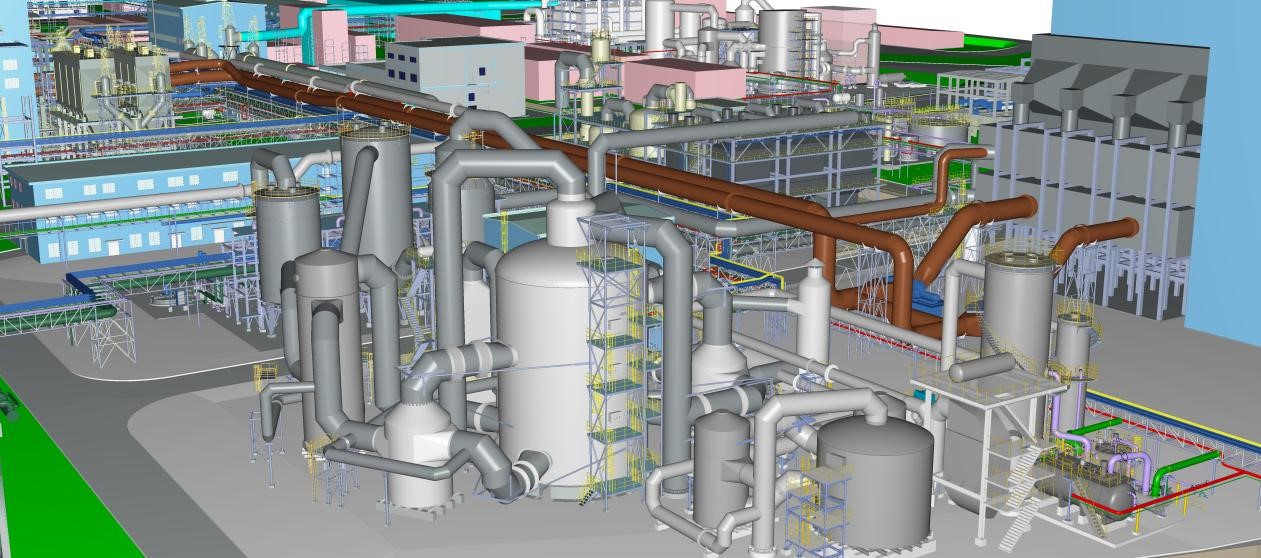

Whole process 3D collaborative design for the whole life of the intelligent plant

The 3D model serves as the foundation for building an intelligent digital plant throughout the entire project lifecycle, from design and procurement to construction and operation. China Nerin has fully utilized the value of the 3D model since the project's inception, applying 3D design in every step to improve design efficiency and quality, reduce errors during construction, and provide robust data support for subsequent operation and maintenance of the smelter.

Despite achieving a fair degree of success, the aim is to continuously strive for greater achievements. In addition to the successful implementation of digital engineering technology at Baiyin Group, China Nerin has also provided customized digital services for several large modern copper smelting enterprises, including Daye Yangxin Hongsheng Copper Co., Ltd., JCC Guoxing Co., Ltd., and ZTS Northern Copper Co., Ltd. These services prioritize safety, efficiency, fine management, and environmental friendliness. China Nerin strives to develop comprehensive digital technologies for the entire business and industry, providing the "Nerin driving forces" necessary for the high-quality development of its customers.