30

2025-05

China Nerin: NDI Digital and Intelligent Solutions Empower High-Quality Development of the Non-ferrous Metal Industry

In the current era of rapid global technological development, digitalization and intelligence have become crucial driving forces for the transformation and upgrading of the non-ferrous metal industry. Based on the development needs of the industry, China Nerin Engineering Co., Ltd. (hereinafter referred to as "China Nerin"), leveraging its profound accumulation in the field of non-ferrous metal engineering technology and its keen insight into cutting-edge information technologies, has independently developed the NDI product — a full-process integrated digital and intelligent solution for the non-ferrous industry chain. This provides an effective and innovative practical path for the digital and intelligent transformation of the non-ferrous metal industry.

Emerging at the Right Time: Focusing on Industry Needs and Setting the Direction for Transformation

After long-term technological accumulation and in-depth industrial cultivation, the non-ferrous metal industry has established a relatively complete industrial system and achieved remarkable results in terms of production capacity scale and technological innovation. However, in the face of adjustments in the global economic landscape and a new wave of technological revolutions, the industry urgently needs to achieve a transition of development drivers through digital and intelligent transformation and move towards a stage of higher-quality development.

Currently, the non-ferrous metal industry is in a critical period of optimizing its industrial structure and improving development quality and efficiency. Although the traditional production model plays an important role in ensuring resource supply, there is still room for improvement in areas such as refined management, comprehensive resource utilization, and production efficiency enhancement. For example, some enterprises have not fully unleashed the potential of digital and intelligent technologies in fields such as production process collaboration, data value exploration, and the application of green and low-carbon technologies. With the market imposing increasingly stringent requirements for product quality, production efficiency, safety, environmental protection, and green and low-carbon development, the deep integration of information technology and operational technology has become an inevitable choice for the industry to break through development bottlenecks and enhance core competitiveness.

The NDI product deeply integrates the development needs of the industry with technological innovation achievements, helping enterprises optimize production processes, improve resource utilization efficiency, strengthen green development capabilities, and promote the high-quality and sustainable development of the non-ferrous metal industry in the wave of digitalization and intelligence.

Technology Empowerment: Building a Technological System and Innovating Platform Architecture

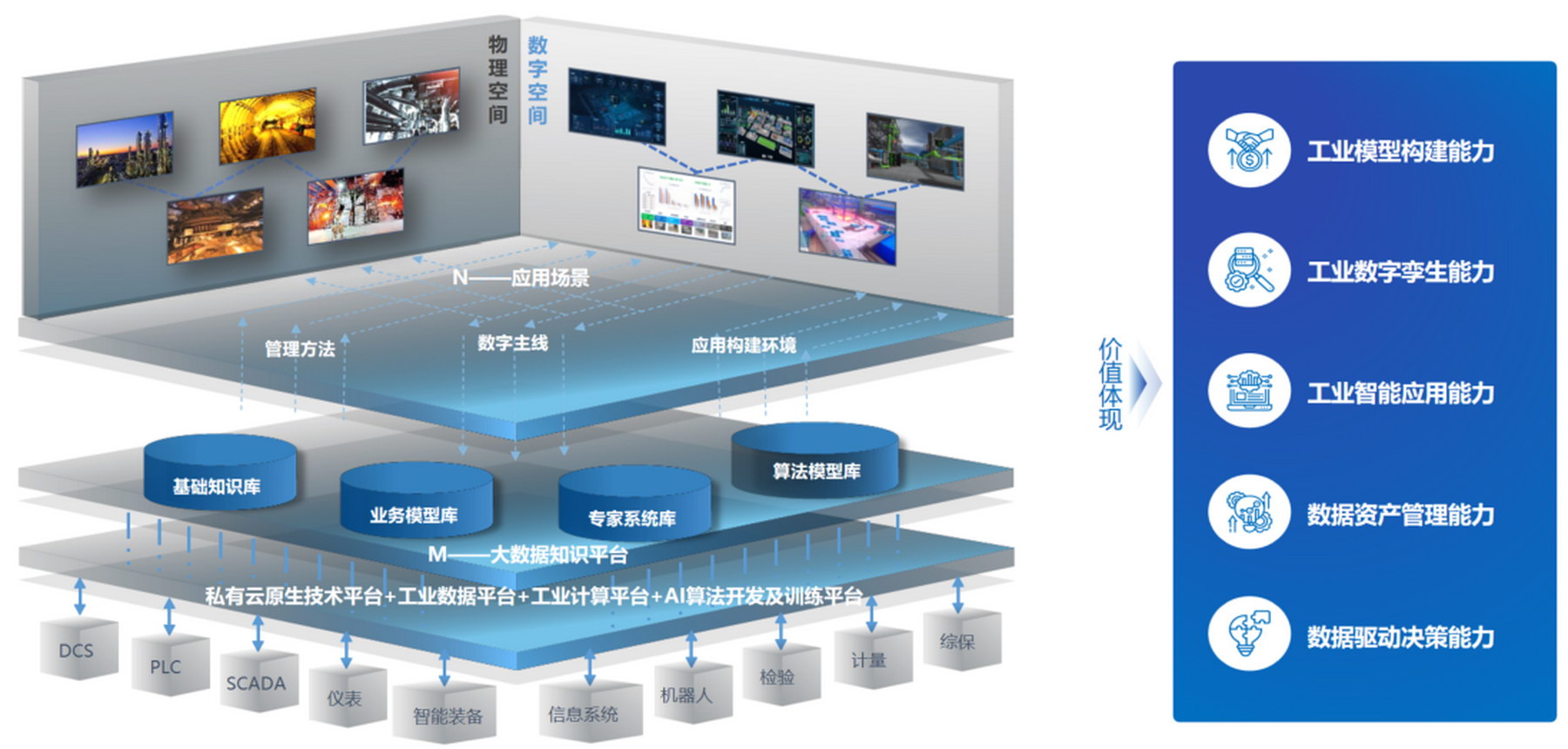

The NDI product takes the "Nerin Intelligent" industrial Internet platform as its core technological foundation, deeply integrating new-generation information technologies such as cloud computing, big data, the Internet of Things, and artificial intelligence. The "Nerin Intelligent" platform has established stable and reliable industrial Internet infrastructures, breaking down information barriers between equipment, systems, and personnel in the production process of non-ferrous metal enterprises, achieving interconnection and providing solid guarantees for the real-time collection, high-speed transmission, and secure storage of massive production data. Its powerful computing and data processing capabilities lay a solid foundation for the NDI product to efficiently analyze and deeply explore complex production data.

In February 2025, the NDI product achieved a key technological breakthrough by integrating the DeepSeek large model. Relying on the rich corpus training results of the DeepSeek large model, as well as its powerful semantic understanding, knowledge reasoning, and complex task processing capabilities, the NDI product has achieved a qualitative leap in data analysis and insight, enterprise knowledge management, and resource optimization and allocation. At a non-ferrous metal smelter, the NDI product accurately identified and early-warned potential equipment failures in real-time by analyzing equipment operation data, effectively avoiding abnormal shutdowns of key production equipment and reducing significant economic losses. At the same time, by optimizing the parameters of the pyrometallurgical process, it significantly improved the product pass rate. In the mining field, the NDI product scientifically dispatches mining equipment and personnel tasks based on real-time information and AI algorithms, significantly improving ore mining efficiency and reducing energy consumption.

The NDI product innovatively adopts the architecture of "3 major systems + 6 scenarios + N kinds of applications", providing highly specialized digital and intelligent upgrade services for the industry. The 3 major systems cover infrastructure platform construction, data resource management, and operational intelligence empowerment; they focus on 6 core scenarios including engineering digitalization, production process digitalization, operational digitalization, equipment intelligence, production system intelligence, and decision-making intelligence; and can flexibly customize and develop N kinds of applications according to the individual needs of customers, comprehensively meeting the diverse digital and intelligent transformation needs of different enterprises. Based on the "Nerin Intelligent" industrial Internet platform technology, China Nerin participated in the compilation of the national standard "Industrial Internet Platform - Heterogeneous Protocol Compatible Adapter Requirements" (GB/T 43738-2024), effectively promoting interconnection in the industrial field; the industrial data platform won the outstanding case award for "Software Empowering Manufacturing Industry Upgrading" and has been launched in many enterprises, significantly improving their data management capabilities; the projects of "Non-ferrous Metallurgy Efficient Conversion, Precise Regulation, and Intelligent Automation System" and the "Key Generic Technologies for Typical Heavy Metal Pollution Source Reduction in Zinc Electrolysis and Large Packaged Equipment" won the second prize of the 2023 and 2020 National Award for Science and Technology Progress respectively; the engineering digital platform won the "Certificate of Achievement" awarded by Bentley U.S. for its full lifecycle services.

Diverse Practices: Deepening Scenario Applications and Demonstrating Implementation Effects

Relying on multiple advantages in data definition, process integration, logical control, equipment empowerment, platform integration, etc., China Nerin has successfully provided customized digital and intelligent solutions for many enterprises such as Jiangxi Copper Corporation and Baiyin Group, injecting strong momentum into the construction of smart mines and smart plants.

In the field of smart mine construction, the Lead-Zinc-Silver Mine Project in Yinzhushan Mining Area of Lengshuikeng Ore Field in Guixi City, Jiangxi Province, undertaken by China Nerin on an EPC basis, is a model example. The NDI product achieves one-stop efficient management of the entire data assets of the mine. Through in-depth analysis of multi-source data such as geology, mining, and mineral processing, it provides a scientific and accurate basis for mining plan development. In the production control link, mining, mineral processing, and other processes achieve intelligent precision control and collaborative and efficient management. New industrial applications such as unmanned equipment operation, intelligent dispatching systems, and integrated production control have created a model for modern smart mines, effectively improving mining efficiency and significantly reducing labor costs and safety risks.

In terms of smart plant construction, the Jiangtong Guoxing Smart Plant is a typical representative of the in-depth application of the NDI product. The team of China Nerin, with their profound understanding of copper smelting technology, carried out multiple optimization and innovation projects throughout the entire process from engineering design and construction to production operation and operation management around the process flow of "side-blown furnace smelting + multi-lance top-blown converting + rotary anode furnace refining + electrolysis with permanent stainless steel cathodes". Many intelligent equipment were applied to the copper smelting process for the first time, such as the intelligent lance adjustment system for top-blown furnace, robots for cathode stripping and anode preparation. The comprehensive construction of the unified basic platform, integrated control center, "side-blown + top-blown" expert system, and integrated production operation management application system has created a new model for the construction of smart non-ferrous metal smelters. The NDI product comprehensively upgrades the smelting process flow in terms of digitalization and intelligence. Through the precise optimization of process parameters in smelting, converting, and other links by the expert system, it significantly improves the production automation level and product quality; the integrated production operation management and control system achieves collaborative management of multiple businesses, helping enterprises to grasp production operation dynamics in real-time, optimize production plans and scheduling decisions, and reduce operating costs.

At Baiyin Nonferrous Group, the diverse scenario applications of the NDI product have also achieved remarkable results. In the automation system upgrade, the expert system designed and implemented by China Nerin covers the entire flash smelting process of the copper company of Baiyin Group, achieving interconnection of equipment data in the smelting, anode refining, and sulfuric acid plants. It helped the company achieve a "one-time successful commissioning of the process" in the flash smelting technology improvement project in 2019, breaking the industry's record in first feed. The project was awarded the first batch of digital plant in Gansu Province the following year. In terms of production process digitalization, the self-developed flash smelting furnace and converter expert system solved problems such as matte grade, temperature, and slag type control, enabling intelligent control of production processes that were difficult to precisely control relying on the experience of skilled operators. The intelligent production consumption optimization and control platform built relying on the NDI product helped Baiyin Group be selected as a pilot demonstration project for the big data industry by the Ministry of Industry and Information Technology. After its launch, the proportion of low-grade materials in the flash furnace increased by 10%, the production efficiency of the converter increased by 0.6 heats/day, and the costs and consumption significantly decreased. The whole-process 3D collaborative design runs through the entire project lifecycle, providing data support for plant construction, operation and maintenance, comprehensively promoting the high-end, intelligent, and green transformation of Baiyin Group.

Future Launch: Deepening Innovation Exploration and Broadening Application Boundaries

From technological breakthroughs to industry practices, the NDI product has demonstrated strong innovation momentum. With the continuous iteration of new-generation information technologies, the NDI product will usher in a broader development space. In the future, China Nerin will continue to increase R&D investment and deepen technological innovation. At the technological level, it will further rely on its profound process technology accumulation to explore the in-depth application of artificial intelligence and large models in the non-ferrous metal industry and continuously optimize core functions such as data analysis, knowledge management, and resource allocation; it will strengthen the integration with emerging technologies such as 5G and blockchain to comprehensively improve data transmission speed, security, and reliability.

In terms of application expansion, China Nerin will rely on the NDI product to actively explore innovative applications in more fields such as smart mines, smart smelters, and smart cities. In the field of smart mines, it will deepen cooperation with enterprises in the industry and fully promote the construction of unmanned and green mines; in the field of smart smelters, it will assist enterprises in achieving low-carbon and green development goals; in the field of smart cities, it will apply the technologies and experience accumulated in the non-ferrous metal industry to urban infrastructure construction and management, contributing to the intelligent development of cities.

The NDI product has achieved remarkable results in the non-ferrous metal industry and has become a key force in promoting the digital and intelligent transformation of the industry. Looking forward to the future, with continuous technological innovation and expansion of application fields, China Nerin will rely on the NDI product to continuously output more "Nerin technologies" and "Nerin solutions", helping the non-ferrous metal industry accelerate towards more intelligent, efficient, green, and low-carbon development.